Heated Rectangular Tanks

Let Our Experts Help You Succeed! Contact us today to receive a FREE, NO OBLIGATION estimate.

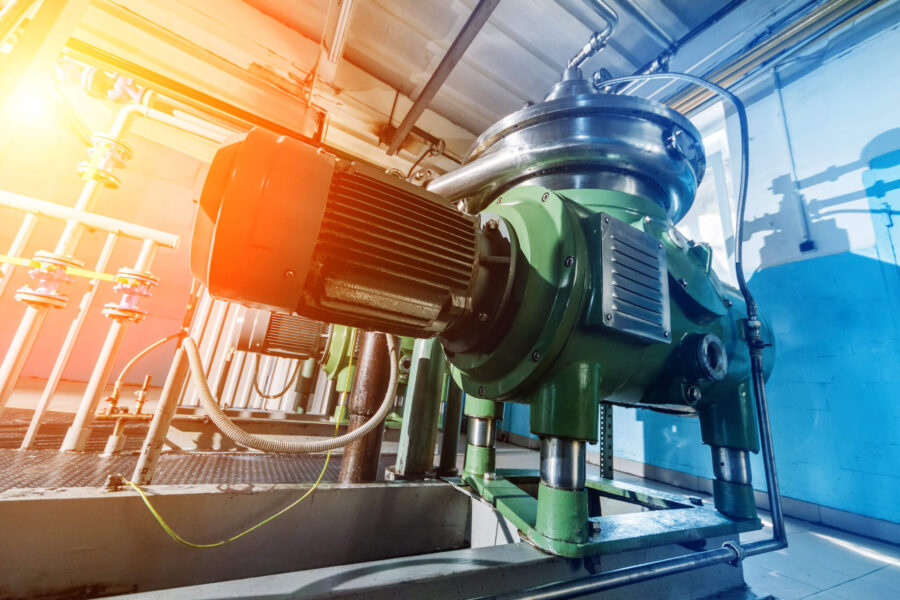

Rectangular tanks may be used as compound melters or as dipping tanks for wax, plastic tooling coating or potting material. The most common uses include cleaning, degreasing, or dip coating of machined parts and tools with wax, ethyl-cellulose compound or other rust preventing material.

Custom Built

Sta-Warm rectangular compound melting tanks are adaptable to countless industrial melting and dipping applications because each tank is custom built to basic size and shape requirements established by the user.

Sta-Warm basic construction and heating application is sufficiently flexible to accommodate itself to extra-ordinary shapes and sizes as required. For instance, a 1,000 gal. tank of “T” shape with sloping bottom has been built and is being used successfully for dipping the liners of household refrigerators. Long, lean proportions or short, square, deep shapes can be made to suit the general design of particular parts to be dipped. Temperature ranges to suit heat requirements of various compounds can be engineered as required, as can various types of outlets, valves, dipping baskets, plungers for displacing materials, lids, partitions, etc.

Applications

Sta-Warm rectangular tanks may be used as compound melters or as dipping tanks. Probably the most common uses include cleaning, degreasing, or dip coating of machined parts and tools with wax, ethyl-cellulose compound or other rust preventing material.

Designed with 36 heating circuits cemented to within 3” of top of sidewalls. Heat density; 3 watts per sq. in. of tank wall and bottom surface area. A 1” wheel type gate valve for draining contents was located inside of the heating chamber to avoid freezing in the valve. Built with hinged, insulated lid and with perforated partition for melting cold material separately from dipping chamber. A disconnect switch was included.

Basic Construction

To produce a ruggedly constructed tank that will withstand many years of steady use, a welded steel inner tank plus sheet steel housing and internally welded angle iron legs of desirable length are usually supplied. The most common type of drain outlet is a 1” heated gate valve. Entire sidewall and bottom area of each tank is heavily protected with heat insulating material.

Heating Arrangement

The secret of Sta-Warm’s uniform, low-wattage heat is found in the design of multiple heating circuits which blanket sidewall and bottom areas of the inner tank. Many feet of specially wound resistance wire, arranged in as many circuits as necessary to provide heating zones, are cemented to the tank. High wattage spotty heat is eliminated and so is the tendency to carbonize or burn the tank contents.

The broad distribution of Sta-Warm heat results in low average heat densities of approximately 3 to 6 watts per square inch, increasing the operating efficiency of the unit.

Heat Controls

Various type of heat controls are supplied according to the requirements of a particular installation. Standard spread normally 50°F - 550°F. Special timers, temperature limit, programming and zone controls are available. Along with digital controls.

Voltages

Units may be wired to operate on any practical voltage below 550 volts.

Special Equipment and Accessories

The design features of Sta-Warm Rectangular Tanks can be adapted in may ways to meet operating requirement.

One popular accessory often supplied is a dipping basket of expanded metal. Tanks may have a vertical divider screen, or be built in two sections, so recently added cold material will melt without interfering with the dipping area.

Various styles of electrically heated (or unheated) draw off and drain valves can be installed. Or, electrically heated rigid pipe can be supplied for conveying melted material from one tank to another

or to point of use.

Hinged lids or loose covers, with or without insulation, are available.

Tanks may be built on legs of various lengths, or without legs for bench use. Legs may be equipped with large roller casters to make the tank semi-portable.

Sta-Warm builds a special line of rectangular tanks that are particularly adapted to melting ethyl-cellulose and thermo-plastic compounds.

Quotations and Prices

Sta-Warm rectangular tanks are custom built and prices are based on capacity and voltage of each particular tank. Electrically heated industrial ovens for drying or baking can be designed for your

particular requirement.

Contact us today for your free, no obligation quote.

More Information

Rectangular Tank Spec Sheet

Rectangular Tanks Data Sheet 1

Rectangular Tanks Date Sheet 2

Rectangular Tanks

Heated Tanks

Melting and dispensing asphalt, pitch, waxes, adhesives, plastics, oils, capping compounds, soaps, gels, eutectic salts, and many other industrial compounds.

We Can Melt it All

Uniform Heating and Stable Temperatures, Even in Transit

Sta-Warm heated equipment works well with wax, plastics, oils, eutectic salts, tar, potting compounds, soaps, resin, glue, paraffin, potting compounds, low melt alloys, soy wax, beeswax, gels and deionized water.

Our heated valves, pipe, and flexible hose conveys molten materials without loss of heat or temperature.

We Build to Suit

Custom Engineered Solutions

Sta-Warm engineers have the experience and know-how to design and build the exact installation you need.

We are happy to provide FREE, NO OBLIGATION estimates based on your production data.

We are Built to Last

Celebrating Over 100 Years of Quality

Sta-Warm has been in the business of designing and building electrically heated industrial equipment and accessories since 1921.

Our products are proudly made in the USA and built to stand the test of time. When you buy from Sta-Warm, you know you are getting the highest quality industrial heating equipment on the market.

Contact Us Today

Let Our Experts Help You Succeed

Sta-Warm engineers and technicians have the experience and knowledge to design and build the equipment your company requires.

If you would like more information about our products, or if you would like a FREE, NO OBLIGATION estimate, please contact us today.